Description

Titanium Gate Valves

Titanium and titanium alloys are non-ferrous high chemical activity metals. Titanium materials have oxide films, good stability and self-passivation ability in strong corrosion environment, so titanium valves can resistance a variety of harsh corrosion conditions

Type: Z40H/W

Size:2"-48"

Pressure Range:Class 150∽Class 1500

Working Temp.:≤425°

Material:Carbon steel,Stainless steel,Alloy steel,special material,chromium molybdenum steel,etc.

Medium:Water Steam Oil

Operation: Manual Pneumatic Electric

Applicable standards

Steel gate valves, API 600/API 6D

Steel gate valves, ISO 10434/ISO 14313

Steel valves, ASME B16.34

Face to face, ASME B16.10

End flanges, ASME B16.5

Butt welding ends, ASME B16.25

Inspection and test, API 598

Design Feature

Full port design

OS&Y, Outside screw and yoke

BB, Bolted bonnet

Flexible wedge/solid wedge

Renewable seat

Forged T-Head stem

Handwheel, & Gear box operator

Selectable Grades Of Titanium Gate Valves

|

Material Group |

Castings Grades |

Forgings Grades |

Bar Grades |

|

Titanium Gr. 2 |

B367 Gr.C-2 |

B381 Gr F-2 |

B348 Gr.2 |

|

Titanium Gr. 3 |

B367 Gr.C-3 |

B381 Gr F-3 |

B348 Gr.3 |

|

Titanium Gr. 5 |

B367 Gr.C-5 |

B381 Gr F-5 |

B348 Gr.5 |

|

Titanium Gr. 6 |

B367 Gr.C-6 |

B381 Gr F-6 |

B348 Gr.6 |

|

Titanium Gr. 12 |

B367 Gr.C-12 |

B381 Gr F-12 |

B348 Gr.12 |

|

Titanium Gr. 7 |

B367 Pd7B |

B381 Gr. F-7 |

B348 Gr.7 |

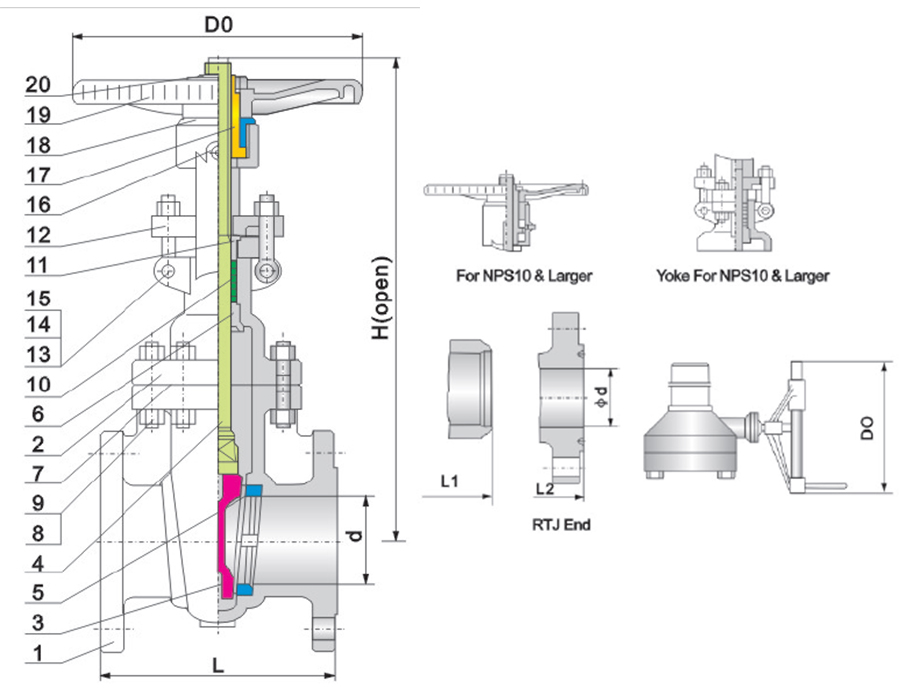

Material of parts:

|

No. |

ASTM Material |

||||

|

Part Name |

Carbon steel |

11/4 Cr-11/2 Mo |

Low-term. Steel |

Stainless steel |

|

|

1 |

Body |

A216-WCB |

A217-WC6 |

A352-LCB |

ASTM A351 CF8M |

|

2 |

Bonnet |

A216-WCB |

A217-WC6 |

A352-LCB |

ASTM A351 CF8M |

|

3 |

Wedge |

A216-WCB+13Cr |

A217-WC6+HF |

A352-LCB+13Cr |

A351-CF8M+STL |

|

4 |

Stem |

A182-F6a |

CR-MO-V |

A182-F6a |

A182-F316 |

|

5 |

Seat Ring |

A105+13Cr |

A182 F11+HF |

A350 LF2+13Cr |

A182-F316+STL |

|

6 |

Stem Back Seat |

A276-410 |

A276-410 |

A276-410 |

A182-F316 |

|

7 |

Bonnet Gasket |

Spiral Wound(Graphite+304/316) |

|||

|

8 |

Bonnet Stud |

A193-B7 |

A193-B16 |

A320-L7 |

A193-B8M |

|

9 |

Bonnet Stud Nut |

A194-2H |

A194-7 |

A194-4 |

A194-8M |

|

10 |

Packing |

Graphite |

|||

|

11 |

Gland |

A276-420 |

A276 420 |

A276-420 |

Stainless steel |

|

12 |

Gland Flange |

A216 WCB |

A217-WC6 |

A352-LCB |

ASTM A351 CF8M |

|

13 |

Eyebolt Pin |

Carbon steel |

A276 420 |

Carbon steel |

Stainless steel |

|

14 |

Bolt |

Carbon steel |

A193-B7 |

Carbon steel |

A193-B8M |

|

15 |

Nut |

Carbon steel |

A194-2H |

Carbon steel |

A194-8M |

|

16 |

Grease Fitting |

Brass + steel |

|||

|

17 |

Yoke sleeve |

Copper Alloy |

|||

|

18 |

Yoke sleeve nut |

Carbon steel |

|||

|

19 |

Handwheel |

Malleable iron |

|||

|

20 |

Handwheel nut |

Carbon steel |

|||

2) Wedge and seat ring may either be solid facing material or a base material equal or better than the body/bonnet material with facing as shown.

150 LB

Dimensions: inches (millimeters)

| Sizes | L | L1 (BW) | H (Open) | W |

|---|---|---|---|---|

| 2" | 7 (180) | 8-1/2 (216) | 14-1/2 (368) | 8 (200) |

| 2-1/2" | 7-1/2 (190) | 9-1/2 (241) | 17 (432) | 8 (200) |

| 3" | 8 (200) | 11-1/8 (283) | 18 (457) | 8-7/8 (225) |

| 4" | 9 (230) | 12 (305) | 22 (559) | 11 (279) |

| 5" | 10 (254) | 15 (381) | 26 (660) | 12-3/4 (325) |

| 6" | 10-1/2 (266) | 15-7/8 (403) | 30 (762) | 14 (356) |

| 8" | 11-1/2 (290) | 16-1/2 (420) | 38-1/2 (978) | 14 (356) |

| 10" | 13 (330) | 18 (457) | 46 (1168) | 18 (457) |

| 12" | 14 (356) | 19 (502) | 55-1/4 (1403) | 20 (508) |

| 14" | 15 (381) | 22 (559) | 60 (1524) | 21-1/2 (546) |

| 16" | 16 (407) | 24 (610) | 74-7/8 (1902) | 24 (610) |

| 18" | 17 (432) | 26 (660) | 79 (2007) | 27 (686) |

| 20" | 18 (457) | 28 (711) | 87-1/2 (2223) | 28 (711) |

| 24" | 20 (508) | 32 (813) | 105 (2667) | 31-1/2 (800) |

| 30" | 24 (610) | 38 (965) | 130 (3302) | 43 (1092) |

| 36" | 28 (711) | 44 (1118) | 162 (4115) | 51 (1295) |

| GEAR OPERATOR RECOMMENDED FOR SIZE 10" AND ABOVE | ||||

300 LB

Dimensions: inches (millimeters)

| SIZES | L/L1 | H (OPEN) | W | |

|---|---|---|---|---|

| 2" | 8-1/2 (216) | 16 (407) | 7-7/8 (200) | |

| 2-1/2" | 9-1/2 (241) | 17-3/8 (442) | 7-7/8 (200) | |

| 3" | 11-1/8 (283) | 19-3/4 (501) | 8-7/8 (225) | |

| 4" | 12 (305) | 23-3/8 (594) | 9-7/8 (251) | |

| 5" | 15 (381) | 23-3/4 (603) | 12-1/2 (318) | |

| 6" | 15-7/8 (403) | 32-1/8 (816) | 14 (356) | |

| 8" | 16-1/2 (420) | 41 (1041) | 15-3/4 (400) | |

| 10" | 18 (457) | 48-3/8 (1229) | 17-3/4 (451) | |

| 12" | 19-3/4 (501) | 57 (1448) | 20 (508) | |

| 14" | 30 (762) | 62-1/2 (1588) | 22 (559) | |

| 16" | 33 (838) | 69 (1753) | 25 (635) | |

| 18" | 36 (914) | 80-1/2 (2045) | 28 (711) | |

| 20" | 39 (991) | 91 (2311) | 35-1/2 (902) | |

| 24" | 45 (1143) | 120-1/2 (3061) | 43 (1092) | |

| GEAR OPERATOR RECOMMENDED FOR SIZE 8" AND ABOVE | ||||

600 LB

Dimensions: inches (millimeters)

| SIZES | L/L1 | H (OPEN) | W | |

|---|---|---|---|---|

| 2" | 11-1/2 (290) | 16-1/2 (420) | 7-7/8 (200) | |

| 2-1/2" | 13 (330) | 18 (457) | 8-7/8 (225) | |

| 3" | 14 (356) | 20-1/8 (511) | 9-7/8 (251) | |

| 4" | 17 (432) | 25 (635) | 14 (356) | |

| 5" | 20 (508) | 30-1/2 (775) | 15-3/4 (400) | |

| 6" | 22 (559) | 33-5/8 (854) | 17-3/4 (451) | |

| 8" | 26 (660) | 42-3/8 (1076) | 20 (508) | |

| 10" | 31 (787) | 49 (1245) | 25 (635) | |

| 12" | 33 (838) | 68-1/2 (1740) | 27 (686) | |

| 14" | 35 (889) | 69 (1753) | 31-1/2 (800) | |

| 16" | 39 (991) | 74 (1880) | 35-1/2 (902) | |

| 18" | 43 (1092) | 84-1/4 (2140) | 43 (1092) | |

| 20" | 47 (1194) | 93-1/2 (2375) | 51 (1295) | |

| 24" | 55 (1397) | 110 (2794) | 51 (1295) | |

| GEAR OPERATOR RECOMMENDED FOR SIZE 8" AND ABOVE | ||||

900 LB

Dimensions: inches (millimeters)

| SIZES | L/L1 | H (OPEN) | W | |

|---|---|---|---|---|

| 2" | 14-1/2 (368) | 26 (660) | 10-1/4 (260) | |

| 3" | 15 (381) | 26-3/8 (670) | 11-1/2 (292) | |

| 4" | 18 (457) | 30 (762) | 14 (356) | |

| 6" | 24 (610) | 40-3/4 (1035) | 20 (508) | |

| 8" | 29 (737) | 51 (1295) | 24 (610) | |

| 10" | 33 (838) | 61 (1549) | 27 (686) | |

| 12" | 38 (965) | 69-1/2 (1765) | 31-1/2 (800) | |

| 14" | 40-1/2 (1029) | 77 (1956) | 35-1/2 (902) | |

| 16" | 44-1/2 (1130) | 82-3/4 (2102) | 43 (1092) | |

| GEAR OPERATOR RECOMMENDED FOR SIZE 6" AND ABOVE | ||||

1500 LB

Dimensions: inches (millimeters)

| SIZES | L/L1 | H (OPEN) | W | |

|---|---|---|---|---|

| 2" | 14-1/2 (368) | 21-1/2 (546) | 11-1/2 (290) | |

| 3" | 18-1/2 (470) | 27-1/8 (689) | 14 (356) | |

| 4" | 21-1/2 (546) | 31-1/2 (800) | 20 (508) | |

| 6" | 27-3/4 (705) | 45 (1143) | 24 (610) | |

| 8" | 32-3/4 (832) | 53-1/2 (1359) | 27 (686) | |

| 10" | 39 (991) | 65 (1651) | 35-1/2 (902) | |

| 12" | 44-1/2 (1130) | 74 (1880) | 43 (1092) | |

| 14" | 49-1/2 (1257) | 83-1/2 (2121) | 51 (1295) | |

| 16" | 54-1/2 (1384) | 88 (2235) | 63 (1600) | |

| GEAR OPERATOR RECOMMENDED FOR SIZE 6" AND ABOVE | ||||

2500 LB

Dimensions: inches (millimeters)

| SIZES | L/L1 | H (OPEN) | W | |

|---|---|---|---|---|

| 2" | 17-3/4 (451) | 24-7/8 (632) | 12 (305) | |

| 3" | 22-3/4 (578) | 36 (914) | 20 (508) | |

| 4" | 26-1/2 (673) | 41-1/2 (1054) | 20 (508) | |

| 6" | 36 (914) | 57 (1448) | 24 (610) | |

| 8" | 40-1/4 (1022) | 63-3/8 (1610) | 24 (610) | |

| GEAR OPERATOR RECOMMENDED FOR SIZE 6" AND ABOVE | ||||