Description

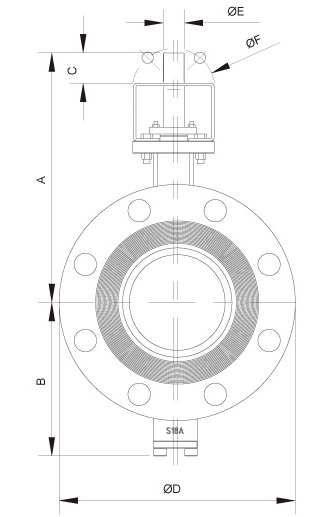

Triple-Offset Butterfly Valves

| Connection | Double flange |

| Size | 3″-80″ for PN10,PN16,Class150; 3″-48″ for PN25,PN40,Class300; 3″-24″ for Class600 |

| Pressure | PN10,PN16,PN25,PN40,Class150,Class300,Class600 |

| Flange standard | ASME B16.5 Class150,Class300,Class600; EN1092 PN16,PN25,PN40 |

| Face to face | ISO 5752, ASME B16.10, API609 Double flanged short pattern |

| Pressure test | API 598, ISO 5208 Rate A, ANSI B16.104(ANSI/FCI 70-2)Class Ⅵ |

| Temperature | -29°C to +538°C |

| Operator | Lever,Gear box,Pneumatic actuator,Electric actuator |

| No. | Part name | Material | |

| 1 | Body | WCB | CF8M |

| 2a | Disc | WCB,CF8 | CF8M |

| 2b | Disc sealing | UNS31803(duplex)+graphite | |

| 2c | Disc sealing retainer | SS304 | SS316 |

| 2d | Disc sealing retainer screw | SS304 | SS316 |

| 3 | Seat welded surface | Stellite Gr.21 | |

| 4 | Shaft | 17-4 PHSS,1.4462 | |

| 5 | Packing gland | CF8 | |

| 6 | Bottom cover | Same as body | |

| 7 | Cover seal | Graphite | |

| 8 | Thrust washer | SS316 | |

| 9 | Bracket | WCB | CF8M |

| 10 | Retaining ring | SS304 | |

| 11 | Packing | RPTFE, Graphite | |

| 12 | Packing ring | SS316 | |

| 13 | Bearing | SS316+PTFE | |

| 14 | Thrust bearing | SS316 | |

| 15 | Key | SS316 | |

| 16 | Bolt | SS304 | |

| 17 | Bolt | SS304 | |

| 18 | Bolt | SS304 | |

| 19 | Nut | SS304 | |

| SIZE | A | B | C | D | E | Top Flange | L | WT(kg) | ||||

| Class150 | PN10 | PN16 | PN25 | |||||||||

| DN | INCH | Class150,PN10,PN16,PN25 | ||||||||||

| 80 | 3″ | 260 | 125 | 17.5 | 190 | 200 | 200 | 200 | 14 | F07 | 114 | 30 |

| 100 | 4″ | 290 | 141 | 17.5 | 230 | 220 | 220 | 235 | 14 | F07 | 127 | 40 |

| 125 | 5″ | 310 | 150 | 17.5 | 255 | 250 | 250 | 270 | 14 | F07 | 140 | 45 |

| 150 | 6″ | 330 | 165 | 18.5 | 280 | 285 | 285 | 300 | 17 | F10 | 140 | 50 |

| 200 | 8″ | 385 | 214 | 24.5 | 345 | 340 | 340 | 360 | 22 | F10 | 152 | 85 |

| 250 | 10″ | 425 | 243 | 24.5 | 405 | 395 | 405 | 425 | 22 | F10 | 165 | 120 |

| 300 | 12″ | 490 | 286 | 30 | 485 | 445 | 460 | 485 | 27 | F12 | 178 | 160 |

| 350 | 14″ | 525 | 312 | 30 | 535 | 505 | 520 | 555 | 27 | F12 | 190 | 195 |

| 400 | 16″ | 545 | 350 | 39 | 595 | 565 | 580 | 620 | 36 | F14 | 216 | 255 |

| 450 | 18″ | 580 | 383 | 49 | 635 | 615 | 640 | 670 | 46 | F16 | 222 | 310 |

| 500 | 20″ | 640 | 407 | 49 | 700 | 670 | 715 | 730 | 46 | F16 | 229 | 390 |

| 600 | 24″ | 690 | 484 | 60 | 815 | 780 | 840 | 845 | 55 | F25 | 267 | 565 |

| 700 | 28″ | 720 | 525 | 130 | 925 | 895 | 910 | 960 | 80 | F30 | 292 | |

| 750 | 30″ | 750 | 550 | 130 | 985 | 80 | F30 | 318 | ||||

| 800 | 32″ | 760 | 600 | 130 | 1060 | 1015 | 1025 | 1085 | 98 | F30 | 318 | |

| 900 | 36″ | 795 | 660 | 150 | 1170 | 1115 | 1125 | 1185 | 120 | F35 | 330 | |

| 1000 | 40″ | 815 | 720 | 180 | 1290 | 1230 | 1255 | 1320 | 130 | F35 | 410 | |

| 1050 | 42″ | 850 | 750 | 180 | 1345 | 150 | F35 | 410 | ||||

| 1200 | 48″ | 995 | 825 | 200 | 1510 | 1455 | 1485 | 180 | F40 | 470 | ||

| SIZE | A | B | C | D | E | Top Flange | L | WT(kg) | ||

| Class300 | PN40 | |||||||||

| DN | INCH | Class300,PN40 | ||||||||

| 80 | 3″ | 260 | 100 | 17.5 | 210 | 200 | 14 | F07 | 180 | 30 |

| 100 | 4″ | 290 | 124 | 17.5 | 255 | 235 | 14 | F07 | 190 | 40 |

| 125 | 5″ | 330 | 144 | 18.5 | 280 | 270 | 17 | F10 | 200 | 60 |

| 150 | 6″ | 350 | 150 | 24.5 | 320 | 300 | 22 | F10 | 210 | 75 |

| 200 | 8″ | 415 | 204 | 30 | 380 | 375 | 27 | F12 | 230 | 115 |

| 250 | 10″ | 455 | 238 | 39 | 445 | 450 | 36 | F14 | 250 | 170 |

| 300 | 12″ | 490 | 268 | 39 | 520 | 515 | 36 | F14 | 270 | 170 |

| 350 | 14″ | 545 | 294 | 49 | 585 | 580 | 46 | F16 | 290 | 315 |

| 400 | 16″ | 575 | 320 | 60 | 650 | 660 | 55 | F25 | 310 | 415 |

| 450 | 18″ | 660 | 341 | 60 | 710 | 685 | 55 | F25 | 330 | 490 |

| 500 | 20″ | 700 | 383 | 80 | 775 | 755 | 75 | F30 | 350 | 600 |

| 600 | 24″ | 785 | 442 | 80 | 915 | 890 | 75 | F30 | 390 | 900 |

| 700 | 28″ | 800 | 590 | 150 | 1035 | 120 | F35 | 430 | ||

| 750 | 30″ | 830 | 600 | 180 | 1090 | 130 | F35 | 450 | ||

| 800 | 32″ | 860 | 720 | 200 | 1150 | 170 | F40 | 470 | ||

| 900 | 36″ | 940 | 780 | 200 | 1270 | 180 | F40 | 510 | ||

| 1000 | 40″ | 910 | 750 | 250 | 1240 | 200 | F48 | 550 | ||

| 1050 | 42″ | 950 | 800 | 250 | 1290 | 210 | F48 | 570 | ||

| 1200 | 48″ | 1000 | 850 | 250 | 1465 | 220 | F48 | 630 | ||

| SIZE | A | B | C | D | E | Top Flange | L | WT(kg) | |||

| Class600 | PN63 | PN100 | |||||||||

| DN | INCH | Class600,PN63,PN100 | |||||||||

| 80 | 3″ | 260 | 145 | 17.5 | 210 | 215 | 230 | 14 | F07 | 180 | 50 |

| 100 | 4″ | 298 | 185 | 24.5 | 275 | 250 | 265 | 22 | F10 | 190 | 70 |

| 125 | 5″ | 400 | 200 | 30 | 330 | 295 | 315 | 27 | F12 | 200 | 90 |

| 150 | 6″ | 420 | 216 | 39 | 355 | 345 | 355 | 36 | F14 | 210 | 125 |

| 200 | 8″ | 445 | 265 | 39 | 420 | 415 | 430 | 36 | F14 | 230 | 200 |

| 250 | 10″ | 505 | 315 | 49 | 510 | 470 | 505 | 46 | F16 | 250 | 315 |

| 300 | 12″ | 600 | 362 | 49 | 560 | 530 | 585 | 46 | F16 | 270 | 435 |

| 350 | 14″ | 610 | 390 | 60 | 605 | 600 | 655 | 55 | F25 | 290 | 485 |

| 400 | 16″ | 680 | 440 | 60 | 685 | 670 | 55 | F25 | 310 | 685 | |

| 450 | 18″ | 683 | 460 | 80 | 745 | 75 | F30 | 330 | 815 | ||

| 500 | 20″ | 795 | 526 | 80 | 815 | 75 | F30 | 350 | 1050 | ||

| 600 | 24″ | 885 | 623 | 940 | F35 | 390 | 1600 | ||||

| 700 | 28″ | ||||||||||

| 750 | 30″ | ||||||||||

| 800 | 32″ | ||||||||||

| 900 | 36″ | ||||||||||

| 1000 | 40″ | ||||||||||

| 1050 | 42″ | ||||||||||

| 1200 | 48″ | ||||||||||