Description

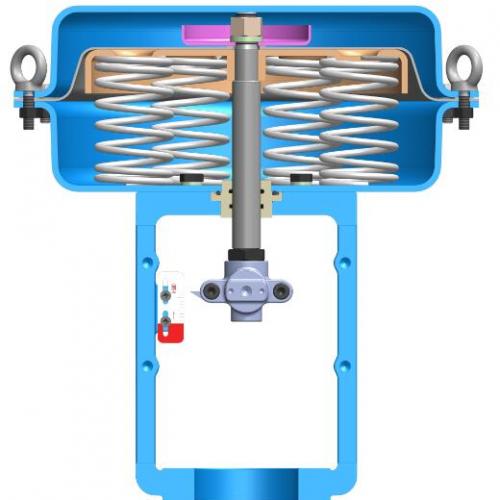

G641J Reciprocating pneumatic diaphragm valve

G641J reciprocating pneumatic diaphragm valve is specially designed to control non-corrosive or general corrosive media. There is no lining on the inner surface of the valve body or covered with a variety of optional rubber. The reciprocating pneumatic diaphragm valve is suitable for different working temperatures and fluid pipelines. Applicable Temperature of Reciprocating Pneumatic Diaphragm Valve:<85, <100, <120, <150 (according to lining and diaphragm material)

Pressure level: PN0.6, 1, 1.6

Material Science

Body: cast iron, ductile iron, carbon steel, stainless steel.

Bonnet: cast iron, ductile iron, carbon steel, stainless steel.

Lining: no lining, rubber.

Diaphragm: Rubber

Disc: cast iron and carbon steel.

Cylinder: ductile iron

Piston: carbon steel

Stem: carbon steel

Hand wheel: Cast Iron

Lining layer: EDM test

Test and inspection according to GB/T13297 standard

Nominal pressure: PN (Mpa)

Valve body: PN * 1.5

Sealing: PN x 1.1

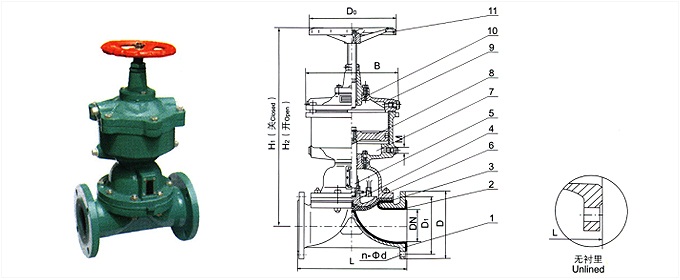

Parts List: 1, Body 2, Body Lining 3, Diaphragm 4, Disc 5, Lower Stem 6, Cover 7, Cylinder 8, Piston 9, Cylinder Head 10, Upper Stem 11, Handwheel

Main dimensions and weight

|

DN

mm |

PN

MPa |

WP

MPa |

L

(mm) |

D

(mm) |

D1

(mm) |

n-φd

(mm) |

F

(mm) |

H1

(mm) |

H2

(mm) |

D0

(mm) |

B

|

Air Pressure

MPa |

Air couple

in |

Air capacity

cm3 |

Weight Kg |

|

15

|

0.6

|

0.6

|

125

|

95

|

65

|

4-14

|

2

|

|

|

|

|

|

|

|

|

|

20

|

139

|

105

|

75

|

4-14

|

2

|

|

|

|

|

|

|

|

|

||

|

25

|

145

|

115

|

85

|

4-14

|

2

|

250

|

264

|

120

|

94

|

0.4

|

10×1

|

2.395×102

|

6.5

|

||

|

32

|

160

|

140

|

100

|

4-18

|

2

|

3025

|

328

|

140

|

120

|

0.4

|

12×1.25

|

6.082×102

|

|

||

|

40

|

180

|

150

|

110

|

4-18

|

3

|

306

|

328

|

140

|

120

|

0.4

|

12×1.25

|

6.082×102

|

|

||

|

50

|

210

|

165

|

125

|

4-18

|

3

|

379

|

405

|

160

|

185

|

0.4

|

12×1.25

|

1.235×102

|

25

|

||

|

65

|

250

|

185

|

145

|

4-18

|

3

|

467

|

502

|

240

|

245

|

0.5

|

16×1.5

|

3.725×103

|

31.5

|

||

|

80

|

300

|

200

|

160

|

4-18

|

3

|

483

|

523

|

240

|

245

|

0.5

|

16×1.5

|

3.725×103

|

62.5

|

||

|

100

|

350

|

220

|

180

|

8-18

|

3

|

565

|

617

|

280

|

330

|

0.5

|

20×1.5

|

9.458×103

|

93.5

|

||

|

125

|

400

|

250

|

210

|

8-18

|

3

|

664

|

732

|

320

|

380

|

0.5

|

20×1.5

|

1.409×104

|

114

|

||

|

150

|

460

|

285

|

240

|

8-22

|

3

|

750

|

830

|

320

|

470

|

0.5

|

20×1.5

|

2.868×104

|

164

|

||

|

200

|

0.4

|

570

|

340

|

295

|

8-22

|

4

|

930

|

1050

|

400

|

470

|

0.5

|

20×1.5

|

4.619×104

|

249

|

|

|

250

|

680

|

395

|

350

|

12-22

|

4

|

|

|

|

|

|

|

|

|