Description

Nickel Gate Valves

The corrosion resistance of Nickel 200 makes it particularly useful for maintaining product purity in the synthetic fibers, and caustic alkalies; and also in structural applications where resistance to corrosion is a prime consideration.

Nickel alloy valves are able to endure the corrosion which the common stainless steel and other materials cannot stand, ensuring the long-term stable operation of pipeline control valves in extremely harsh corrosive medium, such as the transportation and treatment of concentrated alkali

Nickel is distinguished by ductility, strength, and resistance to corrosion and heat. It resists corrosion even at high temperatures and concentrated alkali.

Nickel Gate Valves Industrial Processes Applications

Nickel is a type of industrial gate valve excels in many industrial processes. The following are some of the environments in which Nickel is fully resistant.

• Inorganic Acid • Soil• Hydrated Oxide • Alkanol

• Aldehyde • Ether

• Ketone • Alkali

• Phenol • Organic compounds

Application Of Nickel Gate Valves

We are a professional valve maker that able to offer manual regulating valve used in different industries.- Chemical

- Petrochemical

- Oil & Gas

- Metallurgy

- Desalination

- Power plant desulphurization

Type: Z40H/W

Size:2"-48"

Pressure Range:Class 150∽Class 1500

Working Temp.:≤425°

Material:Carbon steel,Stainless steel,Alloy steel,special material,chromium molybdenum steel,etc.

Medium:Water Steam Oil

Operation: Manual Pneumatic Electric

Applicable standards

Steel gate valves, API 600/API 6D

Steel gate valves, ISO 10434/ISO 14313

Steel valves, ASME B16.34

Face to face, ASME B16.10

End flanges, ASME B16.5

Butt welding ends, ASME B16.25

Inspection and test, API 598

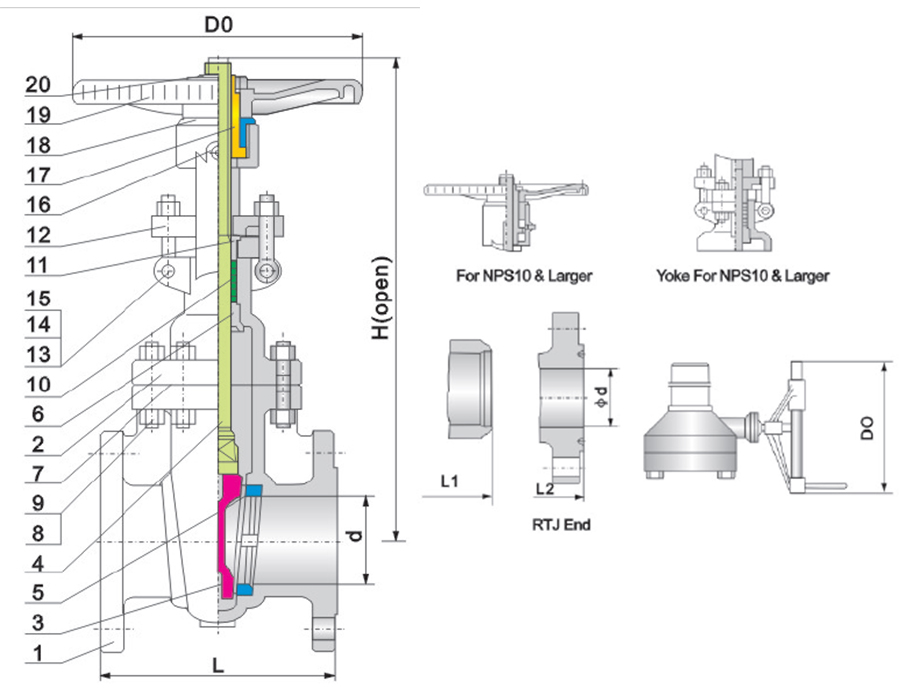

Design Feature

Full port design

OS&Y, Outside screw and yoke

BB, Bolted bonnet

Flexible wedge/solid wedge

Renewable seat

Forged T-Head stem

Handwheel, & Gear box operator

Material of parts:

|

No. |

ASTM Material |

||||

|

Part Name |

Carbon steel |

11/4 Cr-11/2 Mo |

Low-term. Steel |

Stainless steel |

|

|

1 |

Body |

A216-WCB |

A217-WC6 |

A352-LCB |

ASTM A351 CF8M |

|

2 |

Bonnet |

A216-WCB |

A217-WC6 |

A352-LCB |

ASTM A351 CF8M |

|

3 |

Wedge |

A216-WCB+13Cr |

A217-WC6+HF |

A352-LCB+13Cr |

A351-CF8M+STL |

|

4 |

Stem |

A182-F6a |

CR-MO-V |

A182-F6a |

A182-F316 |

|

5 |

Seat Ring |

A105+13Cr |

A182 F11+HF |

A350 LF2+13Cr |

A182-F316+STL |

|

6 |

Stem Back Seat |

A276-410 |

A276-410 |

A276-410 |

A182-F316 |

|

7 |

Bonnet Gasket |

Spiral Wound(Graphite+304/316) |

|||

|

8 |

Bonnet Stud |

A193-B7 |

A193-B16 |

A320-L7 |

A193-B8M |

|

9 |

Bonnet Stud Nut |

A194-2H |

A194-7 |

A194-4 |

A194-8M |

|

10 |

Packing |

Graphite |

|||

|

11 |

Gland |

A276-420 |

A276 420 |

A276-420 |

Stainless steel |

|

12 |

Gland Flange |

A216 WCB |

A217-WC6 |

A352-LCB |

ASTM A351 CF8M |

|

13 |

Eyebolt Pin |

Carbon steel |

A276 420 |

Carbon steel |

Stainless steel |

|

14 |

Bolt |

Carbon steel |

A193-B7 |

Carbon steel |

A193-B8M |

|

15 |

Nut |

Carbon steel |

A194-2H |

Carbon steel |

A194-8M |

|

16 |

Grease Fitting |

Brass + steel |

|||

|

17 |

Yoke sleeve |

Copper Alloy |

|||

|

18 |

Yoke sleeve nut |

Carbon steel |

|||

|

19 |

Handwheel |

Malleable iron |

|||

|

20 |

Handwheel nut |

Carbon steel |

|||

2) Wedge and seat ring may either be solid facing material or a base material equal or better than the body/bonnet material with facing as shown.

150 LB

Dimensions: inches (millimeters)

| Sizes | L | L1 (BW) | H (Open) | W |

|---|---|---|---|---|

| 2" | 7 (180) | 8-1/2 (216) | 14-1/2 (368) | 8 (200) |

| 2-1/2" | 7-1/2 (190) | 9-1/2 (241) | 17 (432) | 8 (200) |

| 3" | 8 (200) | 11-1/8 (283) | 18 (457) | 8-7/8 (225) |

| 4" | 9 (230) | 12 (305) | 22 (559) | 11 (279) |

| 5" | 10 (254) | 15 (381) | 26 (660) | 12-3/4 (325) |

| 6" | 10-1/2 (266) | 15-7/8 (403) | 30 (762) | 14 (356) |

| 8" | 11-1/2 (290) | 16-1/2 (420) | 38-1/2 (978) | 14 (356) |

| 10" | 13 (330) | 18 (457) | 46 (1168) | 18 (457) |

| 12" | 14 (356) | 19 (502) | 55-1/4 (1403) | 20 (508) |

| 14" | 15 (381) | 22 (559) | 60 (1524) | 21-1/2 (546) |

| 16" | 16 (407) | 24 (610) | 74-7/8 (1902) | 24 (610) |

| 18" | 17 (432) | 26 (660) | 79 (2007) | 27 (686) |

| 20" | 18 (457) | 28 (711) | 87-1/2 (2223) | 28 (711) |

| 24" | 20 (508) | 32 (813) | 105 (2667) | 31-1/2 (800) |

| 30" | 24 (610) | 38 (965) | 130 (3302) | 43 (1092) |

| 36" | 28 (711) | 44 (1118) | 162 (4115) | 51 (1295) |

| GEAR OPERATOR RECOMMENDED FOR SIZE 10" AND ABOVE | ||||

300 LB

Dimensions: inches (millimeters)

| SIZES | L/L1 | H (OPEN) | W | |

|---|---|---|---|---|

| 2" | 8-1/2 (216) | 16 (407) | 7-7/8 (200) | |

| 2-1/2" | 9-1/2 (241) | 17-3/8 (442) | 7-7/8 (200) | |

| 3" | 11-1/8 (283) | 19-3/4 (501) | 8-7/8 (225) | |

| 4" | 12 (305) | 23-3/8 (594) | 9-7/8 (251) | |

| 5" | 15 (381) | 23-3/4 (603) | 12-1/2 (318) | |

| 6" | 15-7/8 (403) | 32-1/8 (816) | 14 (356) | |

| 8" | 16-1/2 (420) | 41 (1041) | 15-3/4 (400) | |

| 10" | 18 (457) | 48-3/8 (1229) | 17-3/4 (451) | |

| 12" | 19-3/4 (501) | 57 (1448) | 20 (508) | |

| 14" | 30 (762) | 62-1/2 (1588) | 22 (559) | |

| 16" | 33 (838) | 69 (1753) | 25 (635) | |

| 18" | 36 (914) | 80-1/2 (2045) | 28 (711) | |

| 20" | 39 (991) | 91 (2311) | 35-1/2 (902) | |

| 24" | 45 (1143) | 120-1/2 (3061) | 43 (1092) | |

| GEAR OPERATOR RECOMMENDED FOR SIZE 8" AND ABOVE | ||||

600 LB

Dimensions: inches (millimeters)

| SIZES | L/L1 | H (OPEN) | W | |

|---|---|---|---|---|

| 2" | 11-1/2 (290) | 16-1/2 (420) | 7-7/8 (200) | |

| 2-1/2" | 13 (330) | 18 (457) | 8-7/8 (225) | |

| 3" | 14 (356) | 20-1/8 (511) | 9-7/8 (251) | |

| 4" | 17 (432) | 25 (635) | 14 (356) | |

| 5" | 20 (508) | 30-1/2 (775) | 15-3/4 (400) | |

| 6" | 22 (559) | 33-5/8 (854) | 17-3/4 (451) | |

| 8" | 26 (660) | 42-3/8 (1076) | 20 (508) | |

| 10" | 31 (787) | 49 (1245) | 25 (635) | |

| 12" | 33 (838) | 68-1/2 (1740) | 27 (686) | |

| 14" | 35 (889) | 69 (1753) | 31-1/2 (800) | |

| 16" | 39 (991) | 74 (1880) | 35-1/2 (902) | |

| 18" | 43 (1092) | 84-1/4 (2140) | 43 (1092) | |

| 20" | 47 (1194) | 93-1/2 (2375) | 51 (1295) | |

| 24" | 55 (1397) | 110 (2794) | 51 (1295) | |

| GEAR OPERATOR RECOMMENDED FOR SIZE 8" AND ABOVE | ||||

900 LB

Dimensions: inches (millimeters)

| SIZES | L/L1 | H (OPEN) | W | |

|---|---|---|---|---|

| 2" | 14-1/2 (368) | 26 (660) | 10-1/4 (260) | |

| 3" | 15 (381) | 26-3/8 (670) | 11-1/2 (292) | |

| 4" | 18 (457) | 30 (762) | 14 (356) | |

| 6" | 24 (610) | 40-3/4 (1035) | 20 (508) | |

| 8" | 29 (737) | 51 (1295) | 24 (610) | |

| 10" | 33 (838) | 61 (1549) | 27 (686) | |

| 12" | 38 (965) | 69-1/2 (1765) | 31-1/2 (800) | |

| 14" | 40-1/2 (1029) | 77 (1956) | 35-1/2 (902) | |

| 16" | 44-1/2 (1130) | 82-3/4 (2102) | 43 (1092) | |

| GEAR OPERATOR RECOMMENDED FOR SIZE 6" AND ABOVE | ||||

1500 LB

Dimensions: inches (millimeters)

| SIZES | L/L1 | H (OPEN) | W | |

|---|---|---|---|---|

| 2" | 14-1/2 (368) | 21-1/2 (546) | 11-1/2 (290) | |

| 3" | 18-1/2 (470) | 27-1/8 (689) | 14 (356) | |

| 4" | 21-1/2 (546) | 31-1/2 (800) | 20 (508) | |

| 6" | 27-3/4 (705) | 45 (1143) | 24 (610) | |

| 8" | 32-3/4 (832) | 53-1/2 (1359) | 27 (686) | |

| 10" | 39 (991) | 65 (1651) | 35-1/2 (902) | |

| 12" | 44-1/2 (1130) | 74 (1880) | 43 (1092) | |

| 14" | 49-1/2 (1257) | 83-1/2 (2121) | 51 (1295) | |

| 16" | 54-1/2 (1384) | 88 (2235) | 63 (1600) | |

| GEAR OPERATOR RECOMMENDED FOR SIZE 6" AND ABOVE | ||||

2500 LB

Dimensions: inches (millimeters)

| SIZES | L/L1 | H (OPEN) | W | |

|---|---|---|---|---|

| 2" | 17-3/4 (451) | 24-7/8 (632) | 12 (305) | |

| 3" | 22-3/4 (578) | 36 (914) | 20 (508) | |

| 4" | 26-1/2 (673) | 41-1/2 (1054) | 20 (508) | |

| 6" | 36 (914) | 57 (1448) | 24 (610) | |

| 8" | 40-1/4 (1022) | 63-3/8 (1610) | 24 (610) | |

| GEAR OPERATOR RECOMMENDED FOR SIZE 6" AND ABOVE | ||||