Description

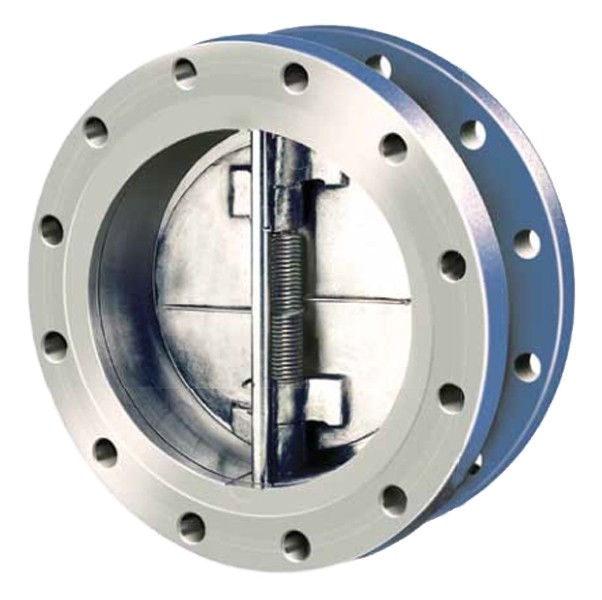

Flanged Dual Plate Wafer Check Valve

Installation

Double Disc Check Valves, also called wafer check valves are designed to be installed between ANSI 150, 300, 600,900 or 1500LB flanges. These valves should not beinstalled between flanges that contain defects.

Prior to installation, the wafer ends and mating flanges should be inspected to ensure gasket surfaces are free of defects. The piping system must also be checked for proper alignment.

Double Disc Check Valves should never be utilized to realign an existing piping system. Our Dual Plate Check Valves are designed for steady flow conditions and can be installed in either horizontal orvertical (flow upwards) pipelines.

1)Horizontal Installation

Double Disc Check Valves, also called wafer check valves are designed to be installed between ANSI 150, 300, 600,900 or 1500LB flanges. These valves should not beinstalled between flanges that contain defects.

Prior to installation, the wafer ends and mating flanges should be inspected to ensure gasket surfaces are free of defects. The piping system must also be checked for proper alignment.

Double Disc Check Valves should never be utilized to realign an existing piping system. Our Dual Plate Check Valves are designed for steady flow conditions and can be installed in either horizontal orvertical (flow upwards) pipelines.

1)Horizontal Installation

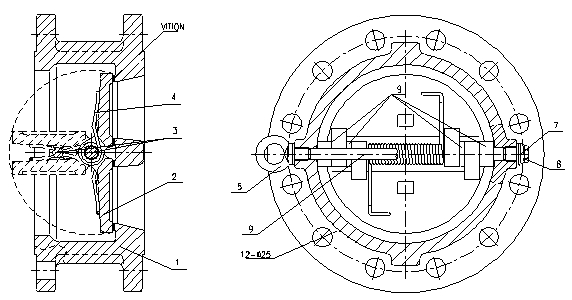

The valve rib must be installed perpendicular to the flow. This is shown in the diagram below. The eyebolt is locateddirectly above the valve rib and can be used to correctly position the valve.

2)Vertical Installation

Check Valves must be installed with the flow direction upward. In this position, the outlet will be above the inlet. It is also necessary to orientate the valve rib such that there is equal loading on the dual plates. This is illustrated in the diagram below. Additional pressure drop should be expected due to the weight of the discs.

When positioning the Check Valve, ensure that the arrow on the body of the valve points in the direction of the flow.

During installation, it is important to support and align the check valve and the adjacent piping. Install a standard, ANSI flange gasket between valve and flange, on both sides. Install lubricated flange bolts and hand tighten. Flange bolts should then be tightened using a star or crisscross pattern to evenly load the bolts.

For efficient function and improved service life, recognized piping standards stipulate placing Check Valves 5 to 10 pipe diameters from any turbulence producing devices.Dual Plate Check Valves are designed for steady flow conditions and are not recommended for low flow,reciprocating flow, pulsating flow, or parallel pumping station. Dual Plate Check Valves are designed to operate properly for flow rates between 5 ft./sec to 10 ft./sec. It is not recommended to exceed the maximum flow rate of 10 ft./sec or the minimum flow rate of 5 ft.

Installation is complete when the wafer ends are flush against the mating flanges and no gaps are present.

Operation

Dual Plate Check Valves are designed to automatically prevent backflow in systems where it is desirable to permit flow in one direction and prevent flow in the opposite direction. When the pump starts and the downstream flow creates the required pressure drop in the forward direction, the Dual Plates will automatically open. When the pump stops and the flow ceases, the torsion of the spring will automatically close the Dual Plates prior to flow reversal. This creates a positive shutoff against flow reversal and eliminates system surges and water hammer.

| Item No. | Part No. | Material |

|---|---|---|

| 1 | Body | A216 WCB |

| 2 | Disc | WCB+ENP |

| 3 | Stop Pin | A276 420 |

| 4 | Spring | Inconnel 625 |

| 5 | Lifting Eye | A29 1025 |

| 6 | Gasket | SS 304 |

| 7 | Gasket | SS304+Graphite |

| 8 | Retainer | A193 B7 |

| 9 | Shaft | 13 Cr |

Maintenance

Our Dual Plate Check Valves are designed for continuous, problem free service and do not require regularly scheduled maintenance.

Leakage

Periodic inspections for leakage should be performed. If leakage is present, check the flange gasket and flange bolttorque. In some situations, it may be necessary to isolate the Check Valve by shutting off upstream and downstream valves. Then remove the Check Valve and inspect the seating surfaces for damage. Dual Plate Check Valves contain Elastomer seats which are vulcanized and bonded to the body castings.They are not adjustable or replaceable in the field.When removing the Check Valve for inspection, please follow the removal instructions presented in this manual. Always relieve pressure from both sides of the Check Valve before inspection. Vibration Verify that flow rate is within acceptable ranges Additionally, verify that the Check Valve is 5 to 10 pipe diameters from any turbulence producing devices Slamming. Remove Check Valve from piping system and inspect the spring. Verify that the spring is providing the proper tension. Restricted Flow if flow is halted at the Check Valve, verify that the flow direction arrow is pointing in the direction of the flow.

Valve Removal

To remove the Check Valve from the pipeline, first isolate the Check Valve and drain the system as much as possible.

Relieve pressure from both sides of the Check Valve by venting the line.

Loosen the outlet flange bolts first then theinlet flange bolts to decompress gasket seals. Attach required lifting equipment and remove the Check Valve from the pipeline.